![]()

|

| FL PERC - September 2003 |

|---|

|

| FL Control Classroom - September 2003 |

Florida Performance Enhancement Relocatable

Classrooms

Orlando, Florida

According to previous research conducted by FSEC, it is estimated that Florida has approximately 25,000 relocatable classrooms to date (FSEC-CR-951-97). At latest count, Orange County Public Schools possesses 3,702 relocatable classrooms in their district of 166 schools. The design and specification process for the FL PERC experiment was similar to that New York although some further modifications were made based on the data collected and information learned from the previous experience. Specifications were further modified for climatical differences, which prompted equipment and insulation changes. The Orange County Public School's Planning and Standards Committee worked closely with FSEC in implementing changes to the typical relocatable classroom that they use in this district. Special attention was made to the lighting layout to ensure optimal distribution. Also, all relocatable classrooms in Orange County are Type IV construction. Type IV construction means all structural members are of non-combustible materials. A building with a metal structure created concerns for ensuring that attention was given to the envelope specifications given the thermal bridging inevitable with steel studs. Another improvement that resulted from the NY project was a "factory friendly" integration of the skylights into the modular construction process. This is explained in the "Lesson Learned" section under the characteristic titled Skylight well.

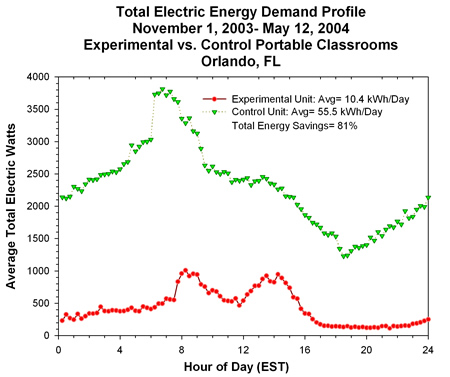

The FL PERC is located at Shingle Creek Elementary School in Orlando, FL where the entire campus is composed of relocatable classrooms. The FL PERC was built by Resun Leasing and South East Modular, in Orlando and Leesburg, FL respectively. Dimensionally, it is a 24’-0” x 36’-0” classroom with a bathroom totaling 864 sq. feet (click here for a view of floor plan 1 and here for a view of floor plan 2). The control classroom was intended to be built by the same manufacturer (South East Modular) but due to scheduling conflicts, it was built by United Modular. However, the base construction is nearly identical from each manufacturer. Both classrooms are occupied and are logging data daily. This testing started October 2003 with data collection beginning in November. The PERC is located sixteen feet south of the control unit (see classroom layout with respect to each other). Measured data shows an overall savings of about 81% were achieved over a year of data collection

| FSEC monitored energy performance in both classrooms. All data was downloaded daily to FSEC via modem. Data summaries can be accessed online at the InfoMonitors web site. Detailed data queries and graphs can also be generated through FSEC's WebGet database. |  |

Construction efficiency related differences between the two FL classrooms are listed in the table below. The results of testing are described below.

NASEO Side-by-Side Study

of FL PERC Specifications of Standard and Energy Efficient Construction |

||

| Characteristic | Standard Relocatable | PERC |

| Floor Insulation | R-14 unfaced Image |

R-14 unfaced Formaldehyde Free |

| Wall Insulation | R-11 faced Image |

R-14 unfaced Formaldehyde Free insulation w/ 1/2" Dens Glass with ¾" polyisocyanurate foam insulation board |

| Exterior Door | HM pressed steel KD (knock down) CECO with solid core R=2.44 | HM pressed steel KD (knock down) CECO with polystyrene core R= 14.8 |

| Ceiling Insulation | R-19 faced | R-30 Icynene spray

foam insulation @ roof deck, Video

clip |

| Roof | Standard dark roof; 0.45 mm black EPDM over ½" Densdeck | Reflective roof; 0.45 mm white EPDM over 5/8" Densdeck http://www.fibertite.com |

| Windows | 1/8" non-tempered bronze tint glass(U=1.03, SHGC=0.84, Vt=0.77) | Low-E Argon gas filled, vinyl framed by Ellison with Solarban 60 glass(U= 0.28, SHGC - 0.39, Vt=0.71) |

| Lights | 1,420 Total Installed Wattage | 984 Total Installed Wattage |

| Outdoor Light | 60 Watt incandescent Manually controlled | 15 Watt CPL, photosensor controlled |

| Skylights | None | (7) 21" dia. Solatube Skylights |

| Interior Floor Finish | 26 oz. rolled carpet | Non-permeable backing, Interface 'Sabi' carpet tile, low VOC glue |

| Heating System | Bard Electric Resistance Heat 10kW heat strip, 35900 BTU heat | Bard QTec Heat Pump, HSPF 7.5 |

| Cooling System | Bard Central Air Conditioning

3.5 ton with ERV,43000 BTU cool SEER 10 |

Bard Qtec Central Heat Pump with

ERV SEER 12 |

| Ventilation System | Fixed CFM during occupancy | CO2 control for ventilation with 3-step fan speed and energy recovery ventilator (click here for more information regarding this ventilation control mechanism) |

| Bathroom Exhaust Fan | Broan, 4 sonne, 100 CFM | Panasonic Whisperlite Fan, 1.3 sonne, 190 CFM |

| Duct Leakage* | CFM25total Return = 318 CFM25total Supply = 485 CFM25out Return = 253 CFM25out Supply = 426 |

CFM25total Return = 325 CFM25total Supply = 420 CFM25out Return = 216 CFM25out Supply = 274 Image |

| Building Leakage* | ACH50 = 2673 ACH50 = 4850 (ACT removed) |

ACH50 = 1107 ACH50 = 1139 (ACT removed) |

| Smoke test - | Infiltration air handler unit

on - 2.60 ach Infiltration air handler unit off - 0.27 ach |

Infiltration air handler unit

on - 0.66 ach Image Infiltration air handler unit off - 0.05 ach Image |

*Leakage Testing performed – December 9, 2003

Lessons Learned - Improvements

Proposed for Next Construction |

||

| Characteristic | Comment | |

| Light Operation | Learning from the NY PERC, we simplified the lighting controls when we specified the Solatube system. The Solatube also had a damper system but they were controlled with a simple manual timer, in the event that the teachers needed the skylights to “shut off”. When a dimmable ballast is specified with a a 3 tube fixture, Advance transformers make a Mark VII that is compatible with continuous dimmable ballast. Sensor switch also makes a photosensor, model #CM-ALC. | |

| Skylight well | Learning from the NY PERC, The FL PERC used the Solatube which included a tube that is standard with the skylight well, thus requiring no extra fabrication for a skylight well area. The Solatube is not insulated and batte insulation was wrapped around the tubes, post construction | |

Insulation |

Use R14 insulation in lieu of R15 because

R15 is only manufactured in 14" widths & 96" lengths, as apposed to R14, which come in rolls and 16" widths (which is more suitable for 16" on center construction, i.e wall cavity). |

|

|

|

|

| Skylight louvers open, electric lights on |

Skylight louvers open, electric lights off |

|

|

|

|

| Control classroom, no skylights |

Close up view of the skylight well parabolic diffuser |

Optimizing the skylight to floor ratio was simulated to determine the size, layout and quantity of skylights that would optimize light levels in the classrooms. A program developed by Heschong Mahone Group, SkyCalc was utilized using various supplemental electrical lighting scenarios. The simulated results of using 5 skylights in NY climate with 3 step dimming lighting operation are shown below:

|

|

|

||

4 skylights |

6 skylights |

8 skylights |

As mentioned in Lessons Learned, the New York PERC lighting

controls were never commissioned to operate automatically therefore

savings would depend on the operators. The control classroom has the option

of only using half the lights and data shows that the teachers in the control

classrooms turned lights off when the classrooms were unoccupied and teachers

in the PERC did not. It was resolved that commissioning of lighting controls

would be a priority in future projects.

For construction status, future data collection, and specifications for other

PERC's, please visit the links below.

|

|

|

Contacts

FSEC would like to especially thank the industry partners who have donated time and equipment in this worthwhile project.

| Company | Contact | Phone | |

| ATEX Distributing | John Michael | john.michael@atexac.com | 352-787-0002 |

| Ellison Windows (Atrium) | Chris Reilly | 800-732-6543 | |

| Heschong Mahone Group | Lisa Heschong | lheschong@h-m-g.com | 916-962-7001 |

| Icynene | Gabe Farkas David Sullivan |

gfarkas@icynene.com local distributor/insulator |

888-946-7325 352-266-6237 |

| Interface Flooring | Liz Rozelle | liz.rozzelle@us.interfaceinc.com | 877-428-0328 |

| Johns Manville | Carlos Bolivar | 305-205-6702 | |

| NASEO | Frank Bishop | fb@naseo.org | 703-299-8800 |

| Orange County Public Schools | Doug Goddard | Goddard@ocps.k12.fl.us | 407-317-3700 |

| Rebuild America - Energy Smarts Schools | Larry Schoff | lschoff@rev.net | 540-961-2184 |

| Resun Leasing | Al Schreier | aschreier@resunleasing.com | 407-240-6767 |

| SensorSwitch Inc. | Maurice Oliver | moliver@sensorswitch.com | 800-727-7483 |

| Solatube | Bob Westfall | bwestfall@solatube.com | 760-597-4406 |

| South East Modular | Jim Ginas | JGinas@SoutheastModular.com | 352-728-2930 |

Project Lead: |

_____________________

Note of Interest: Roof

Icynene spray foam insulation is a spray-in-place soft foam that was applied

to the roof deck of the FL PERC for purpose of lowering air infiltration.

The insulation is made of polyicynene foam, a water-based organic product.

This system provides an air and moisture barrier, wind proofs and seals the

ceiling cavity and fills all crevices against air movement. It also reduces

airborne sound.

Ventilation Method for FL PERC

Wall mounted CO2 Controller model # 8002 w/ display controls, modifies the

ventilation fan speed to operate under these conditions (during occupancy):

- high speed when CO2 levels in the classroom at 1200 ppm or more

- off when CO2 levels in the classroom are at 550 ppm or less

- medium speed when CO2 levels are between 700ppm –1200ppm

Bard CS2000 Energy Management controller detects occupancy and allows the heating/cooling/ventilation systems to operate when the classroom is occupied, and also has pre-cool/pre-heat scheduling